Warning! Modification of a vehicle odometer for fraudulent purposes is against the law! Check your local laws before proceeding. Make sure you have contacted your local law enforcement and government for additional steps, licenses, forms, etc. required to complete this procedure legally.

This guide is aimed at individuals who have swapped in different digital gauge clusters and would like to match their odometer to the actual mileage of their vehicle. I will be focusing on the V5/6 cluster with the solid PCB. I haven’t handled a soft-back V4 cluster so I cannot comment on the differences. Newer clusters from a GD should be the same as a V5/6, but I cannot confirm yet.

This modification is a little on the difficult side. You should be proficient at soldering and have a general understanding of electronics, programming and hexadecimal math.

I have not perfected the math for coding the odometer chip. While I can get the mileage close, I cannot program the chip exactly to some numbers.

Required Tools:

Step 1: Extraction.

The first step is to remove the odometer memory chip from the gauge cluster. This is the most difficult part of the entire project. Start with a cluster removed from your car. I won’t cover removing the gauge cluster.

Remove the rear plastic cover by lifting the ten tabs around the side, and pressing back on the three ‘center’ tabs on the back. A slotted screwdriver helps with this.

![Image]()

Once you have removed the rear cover, you now have to free the stepper motors from the PCB. Locate the four motors. I have circled them in the picture. Using the screwdriver and the pliers, pry back the two tabs on each motor. Be careful not to scratch any traces nearby.

![Image]()

Using a ballpoint pen, push gently on each motor, pushing it away from the board. This is to free the motors a little so they come off easily when you remove the PCB.

Remove the circuit board. You may have to push back the three plastic tabs. If the stepper motors are still stuck onto the board, you can try wiggling the board a bit or push the motors away with a pen.

Once the board is free from the rest of the gauge cluster, you can start to remove the odometer memory chip. First locate the chip. I have circled here in the picture.

![Image]()

![Image]()

In most cases it should be a 93C56EN. You must now de-solder the chip. There are eight connections to the PCB. I have marked the points in the picture. I used a solder vacuum, but use whatever you are most comfortable with.

Once you have the extracted chip, you can start with the programmer.

This guide is aimed at individuals who have swapped in different digital gauge clusters and would like to match their odometer to the actual mileage of their vehicle. I will be focusing on the V5/6 cluster with the solid PCB. I haven’t handled a soft-back V4 cluster so I cannot comment on the differences. Newer clusters from a GD should be the same as a V5/6, but I cannot confirm yet.

This modification is a little on the difficult side. You should be proficient at soldering and have a general understanding of electronics, programming and hexadecimal math.

I have not perfected the math for coding the odometer chip. While I can get the mileage close, I cannot program the chip exactly to some numbers.

Required Tools:

- Flat head screwdriver

- Soldering Iron and solder

- De-soldering tools: Copper braid or a solder-vacuum

- Pliers

- A pen

- Personal computer with a serial port

- Microwire serial programmer (schematic included)

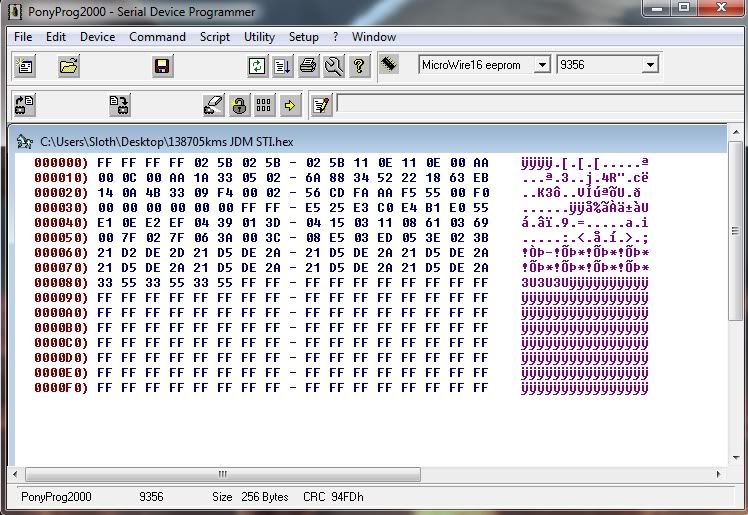

- Serial programming software (Such as PonyProg2000: PonyProg - Serial device programmer )

Step 1: Extraction.

The first step is to remove the odometer memory chip from the gauge cluster. This is the most difficult part of the entire project. Start with a cluster removed from your car. I won’t cover removing the gauge cluster.

Remove the rear plastic cover by lifting the ten tabs around the side, and pressing back on the three ‘center’ tabs on the back. A slotted screwdriver helps with this.

Once you have removed the rear cover, you now have to free the stepper motors from the PCB. Locate the four motors. I have circled them in the picture. Using the screwdriver and the pliers, pry back the two tabs on each motor. Be careful not to scratch any traces nearby.

Using a ballpoint pen, push gently on each motor, pushing it away from the board. This is to free the motors a little so they come off easily when you remove the PCB.

Remove the circuit board. You may have to push back the three plastic tabs. If the stepper motors are still stuck onto the board, you can try wiggling the board a bit or push the motors away with a pen.

Once the board is free from the rest of the gauge cluster, you can start to remove the odometer memory chip. First locate the chip. I have circled here in the picture.

In most cases it should be a 93C56EN. You must now de-solder the chip. There are eight connections to the PCB. I have marked the points in the picture. I used a solder vacuum, but use whatever you are most comfortable with.

Once you have the extracted chip, you can start with the programmer.