I am finishing up the stripping of my interior (just need some dry ice to finish up) and i was wondering how much time it would take to seam weld the whole car, and if not the whole car, what are some of the most vital areas to weld? I would like to do the whole car if its feasible... what kind of prep and stuff would be needed?

Seam Welding

1 reading

AMAXRX

21 - 40 of 43 Posts

After all of this work I would think you would be painting it anyway.geese... i dont know if i actually have the time to do this now... my car would be down for at least a week... probably a month

problem with acid dipping is, its 500$ and then a new paint job for X$$$

I assume that acid dipping takes it down to bare metal. I had some training in collision repair, and they pounded it into our heads that you need to get the steel covered within 30 minutes (IIRC, could be 60) before corrosion sets in. I doubt you could get all your seam welding done in that amount of time.

OT on the Rally subject, but how beneficial would this be on a street car? I'm planning a ton of downtime on my car anyways within the next year or two, so I think I could afford a few more weeks to permit something like this.

OT on the Rally subject, but how beneficial would this be on a street car? I'm planning a ton of downtime on my car anyways within the next year or two, so I think I could afford a few more weeks to permit something like this.

tig is only for welds that will be seen, IMOyou can run it with a mig but I would recommend a tig...takes more time but you have a better weld in the end...

a nice hot mig will penetrate perfectly

and with that many welds, you'd have to be crazy to pick up a tig and dig into that project!!

you don't need to have bare steel primed in 30 minutes..

we have bare steel cars in our shop for months before primer...

as long as you keep water, and fingerprints off them, you're fine..

rust needs moisture, and a free radical to start. if it's clean and dry, you're fine

we have bare steel cars in our shop for months before primer...

as long as you keep water, and fingerprints off them, you're fine..

rust needs moisture, and a free radical to start. if it's clean and dry, you're fine

This really depends on where you live and if your shop is climate controlled.you don't need to have bare steel primed in 30 minutes..

we have bare steel cars in our shop for months before primer...

as long as you keep water, and fingerprints off them, you're fine..

rust needs moisture, and a free radical to start. if it's clean and dry, you're fine

t3hwit and I live in central PA where it's extremly (we're talking rainforest-like!)humid in the summer months. So humid you can't see the mountain across the valley 2 miles away on some hot summer days. Hence why he was saying 30 minutes which seems reasonable to me. If you live in the southwest it might be a totally different story IMO.

Yeah, I'm down here in Louisiana... we too would be lucky to get an hour before the car looks like it was in the junkyard for 30 years..This really depends on where you live and if your shop is climate controlled.

t3hwit and I live in central PA where it's extremly (we're talking rainforest-like!)humid in the summer months. So humid you can't see the mountain across the valley 2 miles away on some hot summer days. Hence why he was saying 30 minutes which seems reasonable to me. If you live in the southwest it might be a totally different story IMO.

AMAXRX-Why don't you just get Paul Eklund/Primitive to do it? You live in the same town (Tigard)!

Joined

·

24 Posts

Drew,

Nice work on that shell prep. Did you do that yourself? It's so nice to see a car on spit like that..Good luck at Laughlin..

AMAXRX,

Seam welding should really be for competition/track cars only. Once you seam weld your car, an "off" on stage, or fender bender on the street can total your car easier than you think.. Strengthening the car via seamwelding transfers energy to different areas than the chassis was designed for. It takes away your "crumple zones".. That's something not many people consider. It's much harder to pull the car back straight after it's been seamwelded, and especially caged. Also, the prep and time it takes to do it properly warrants the $. Don't think seamwelding is a week long process.. Maybe of shell prep/cleaning, welding and paint _after_ it's stripped, dipped, whatever else. Have another way to get around town than the car you're prepping.

If you're planning on beefing up the towers, just gave them stitched.. Wouldn't really bother with that unless it's going to be a stage rally car. A strut tower brace will work fine for rally x.

Also, we're down in Bend, OR if you're ever down this way. We typically have something getting prepped all the time (95 L PGT at the moment) of you'd like to check it out.. There are a bunch of our client's cars up in the Portland area if you'd like to see one stage ready..

Rally On!

Nice work on that shell prep. Did you do that yourself? It's so nice to see a car on spit like that..Good luck at Laughlin..

AMAXRX,

Seam welding should really be for competition/track cars only. Once you seam weld your car, an "off" on stage, or fender bender on the street can total your car easier than you think.. Strengthening the car via seamwelding transfers energy to different areas than the chassis was designed for. It takes away your "crumple zones".. That's something not many people consider. It's much harder to pull the car back straight after it's been seamwelded, and especially caged. Also, the prep and time it takes to do it properly warrants the $. Don't think seamwelding is a week long process.. Maybe of shell prep/cleaning, welding and paint _after_ it's stripped, dipped, whatever else. Have another way to get around town than the car you're prepping.

If you're planning on beefing up the towers, just gave them stitched.. Wouldn't really bother with that unless it's going to be a stage rally car. A strut tower brace will work fine for rally x.

Also, we're down in Bend, OR if you're ever down this way. We typically have something getting prepped all the time (95 L PGT at the moment) of you'd like to check it out.. There are a bunch of our client's cars up in the Portland area if you'd like to see one stage ready..

Rally On!

Seam welding is pretty insane, the amount of work involved. Im planning on stage rallying my RS, but really can't afford to seam weld the whole car. The labor and time involved is just way over my head for the entire process. Seam welding the strut tower areas does seem like a very good idea.

In the end i think that getting seat time is going to be much more valuable than dropping a ton of cash on a car i will probably wreck while im learning the ropes anyway.

In the end i think that getting seat time is going to be much more valuable than dropping a ton of cash on a car i will probably wreck while im learning the ropes anyway.

What/where are the inherently "weak" points on a GC chassis that would benefit from being seam welded aside from the front and rear strut towers?

I'm asking in regard to a street legal road racing application. I understand what seam welding does and how it effects crumple zones. This application will be "walking the line" between street and race car.

I'm asking in regard to a street legal road racing application. I understand what seam welding does and how it effects crumple zones. This application will be "walking the line" between street and race car.

Joined

·

5,855 Posts

That's a good question. I'd like to know too. Where is the medium between weekend warrior and full track whore.What/where are the inherently "weak" points on a GC chassis that would benefit from being seam welded aside from the front and rear strut towers?

I'm asking in regard to a street legal road racing application. I understand what seam welding does and how it effects crumple zones. This application will be "walking the line" between street and race car.

If it were me, I would concentrate on the strut towers, the firewall area inside the front fenders where the 'fenderbrace' goes, and the floor/backseat area inside the passenger compartment.What/where are the inherently "weak" points on a GC chassis that would benefit from being seam welded aside from the front and rear strut towers?

I'm asking in regard to a street legal road racing application. I understand what seam welding does and how it effects crumple zones. This application will be "walking the line" between street and race car.

I did a little with these areas but I also welded in the roll at the same time so I can't make any claims as to how effective those seams would be without the the cage. In my opinion seam welding doesn't make humanly-perceptable difference in feel by itself. Don't get me wrong, I think it makes a difference, but you don't just jump into a car and say "Wow this car has been seam-welded." The real gain is longevity and durablility of the shell.

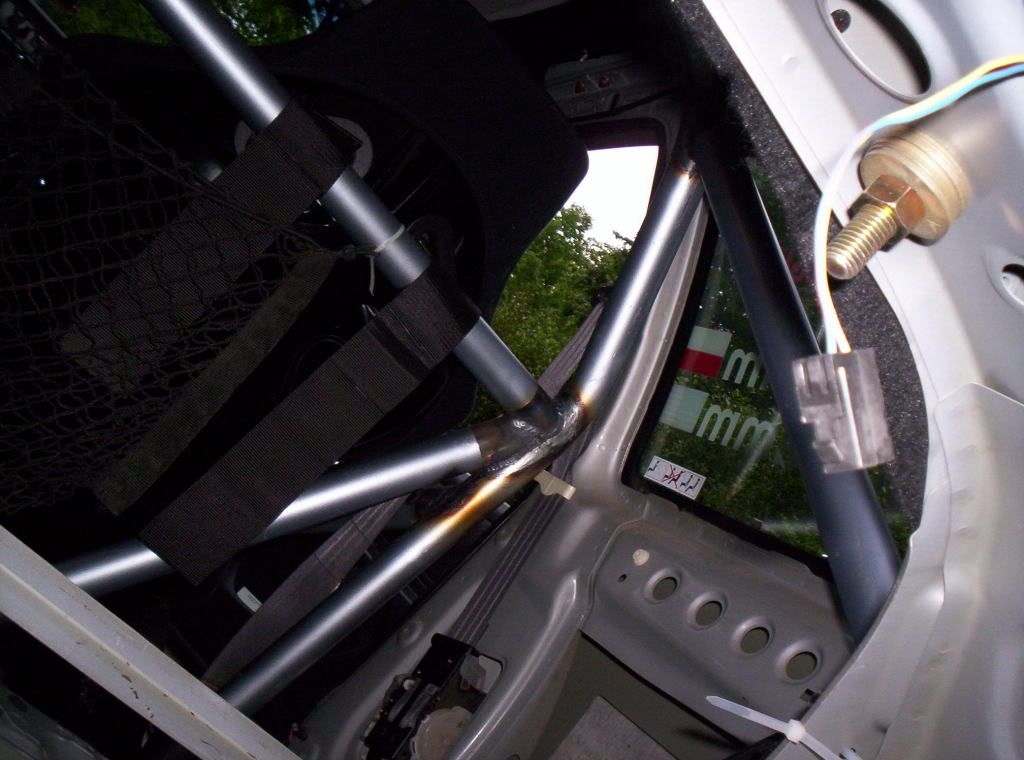

something like this?Durability and longevity are the idea in my application. Since this will still see some mild street use it won't be fully caged, just a custom welded-in roll bar/harness mount.

when we seam welded the STi we had started with the exact sections you are mentioning and I COULD tell a noticable difference the cars roll mid apex and on turn in. The entire setup was the same with the only differences being the welding.If it were me, I would concentrate on the strut towers, the firewall area inside the front fenders where the 'fenderbrace' goes, and the floor/backseat area inside the passenger compartment.

I did a little with these areas but I also welded in the roll at the same time so I can't make any claims as to how effective those seams would be without the the cage. In my opinion seam welding doesn't make humanly-perceptable difference in feel by itself. Don't get me wrong, I think it makes a difference, but you don't just jump into a car and say "Wow this car has been seam-welded." The real gain is longevity and durablility of the shell.

I also have a very sensitive "g-meter/butt dyno". That's why I was always used as our setup and developement drive on our FSAE car...but with that we had data aq to back up my decisions and "feelings"

Nope that wasn't me, its from the USA subaru car. haha.Drew,

Nice work on that shell prep. Did you do that yourself? It's so nice to see a car on spit like that..Good luck at Laughlin..

Thanks for the good luck, from what happened last year right? I ended up not co-driving for laughlin. Certain things happened and I ended up resigning from the team I was racing with. But both my old team and the team I crashed with at laughlin last year finished. So thats good!

Cheers,

Drew Brashler

There 2 or 3 places on the east coast, VT Sportscar and Matt Iorio/Paldin Rally team may be able to do it- Not really sure about west coast.Brydon said it costs $500 to acid dip. Where would you do that?

21 - 40 of 43 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 3.1M

- members

- 81K

- Since

- 2001

A forum community dedicated to Subaru Impreza GC8 and RS owners and enthusiasts. Come join the discussion about performance, modifications, troubleshooting, turbo upgrades, maintenance, and more!

Top Contributors this Month

View All

Seabass20329

38 Replies

bue car

27 Replies

Dirty Sanchez

22 Replies